Introduction:

The construction and mining equipment industry is no stranger to economic downturns. During recessions, manufacturers face numerous challenges, including reduced demand, increased competition, and financial constraints. However, with the right strategies in place, it is possible for manufacturers to not only survive but thrive during challenging times. In this blog post, we will explore effective strategies for surviving a recession as a construction or mining equipment manufacturer, with a focus on reducing costs and maximizing efficiency through the use of AR/VR and immersive technology.

Section 1: Streamlining Sales Meetings

Sales meetings are crucial for manufacturers to connect with potential buyers and secure new contracts. However, they can also be costly, especially when travel expenses and accommodation are involved. To reduce costs, manufacturers can leverage technology to conduct virtual sales meetings. AR/VR technology allows customers to experience equipment virtually, eliminating the need for in-person demonstrations. By using immersive technology, manufacturers can provide an engaging and interactive sales experience while significantly reducing travel expenses.

Section 2: Reevaluating Expos and Trade Shows

Expos and trade shows have traditionally been a valuable avenue for manufacturers to showcase their equipment and connect with potential customers. However, participation in these events can be expensive, with costs ranging from booth rentals to travel expenses. During a recession, it becomes crucial to evaluate the return on investment from these events. Manufacturers can explore alternatives, such as hosting virtual expos or participating in online industry events. By leveraging AR/VR technology, manufacturers can create immersive virtual experiences that replicate the benefits of physical expos while significantly reducing costs.

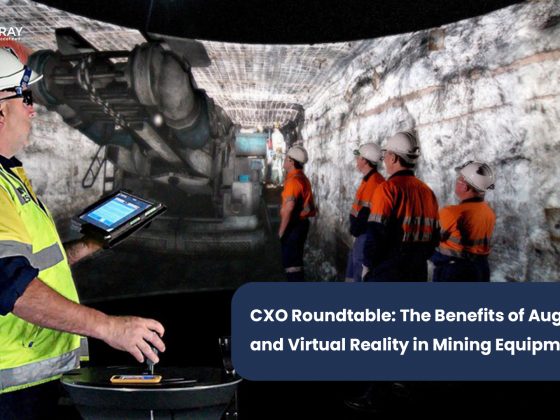

Section 3: Optimizing Employee Training

Employee training is essential for maintaining high-quality standards and ensuring operational efficiency. However, traditional training methods can be time-consuming and costly, especially when considering travel expenses and downtime. By adopting AR/VR technology, manufacturers can provide immersive and interactive training experiences that simulate real-life scenarios without the need for physical equipment. This not only reduces costs but also minimizes machine downtime, allowing employees to receive training while keeping production running smoothly.

Section 4: Minimizing Machine Downtime

During a recession, every minute of machine downtime counts. Unscheduled maintenance and repairs can be a significant drain on resources. AR/VR technology can play a vital role in reducing machine downtime by enabling remote troubleshooting and maintenance support. Technicians can use augmented reality tools to receive guidance from experts, diagnosing issues and performing repairs more efficiently. This technology eliminates the need for costly on-site visits and accelerates the resolution of technical problems.

Conclusion:

Surviving a recession as a construction or mining equipment manufacturer requires a strategic approach to reduce costs, increase efficiency, and maintain a competitive edge. By leveraging AR/VR and immersive technology, manufacturers can streamline sales meetings, reevaluate expos and trade shows, optimize employee training, and minimize machine downtime. These strategies not only reduce expenses but also enhance operational efficiency and customer experiences. By embracing innovative technology, manufacturers can navigate through challenging economic times and position themselves for long-term success. Connect with us to learn more about how our solutions can help your business thrive during recessions and beyond.