With the outbreak of COVID-19, working-from-home and remote access have become the new normal, which applies to global pharmaceutical companies as well. The lack of a digital platform, however, forces pharma auditors to travel to offices and manage quality control, leading to significant delays in the supply chain and increased overall costs. Augray analyses that the digitalization through Augmented Reality/Virtual Reality (AR/VR) of the pharmaceutical audits and other quality control processes will be a potential game-changer in the pharmaceutical industry.

Healthcare sector will provide a boost of $406.7 billion to global GDP by 2030 through utilising the new technologies.

According to the Big Four, AR and VR could add $1.5 trillion to the global economy by 2030. AR will be the primary driver of the market’s growth, growing from a market value of $338.1 billion in 2025 to $1,092.4 billion in 2030. AR is more lucrative than VR currently, however, VR will struggle to keep pace with AR and market worth less than half of AR by 2030, at $450.5 billion. Pharmaceutical has a minor stake in the healthcare sector for AR/VR and most of the innovation is happening around sales. But with the current COVID-19 crisis, pharma manufacturers have understood the importance of digital transformation in manufacturing and quality monitoring. They have started investing in AR technologies to remotely assist medical equipment developers and lab operators to ensure the knowledge transfer is done in a faster and smarter way.

Improving Digital Quality in Pharma Manufacturing using Augmented Reality

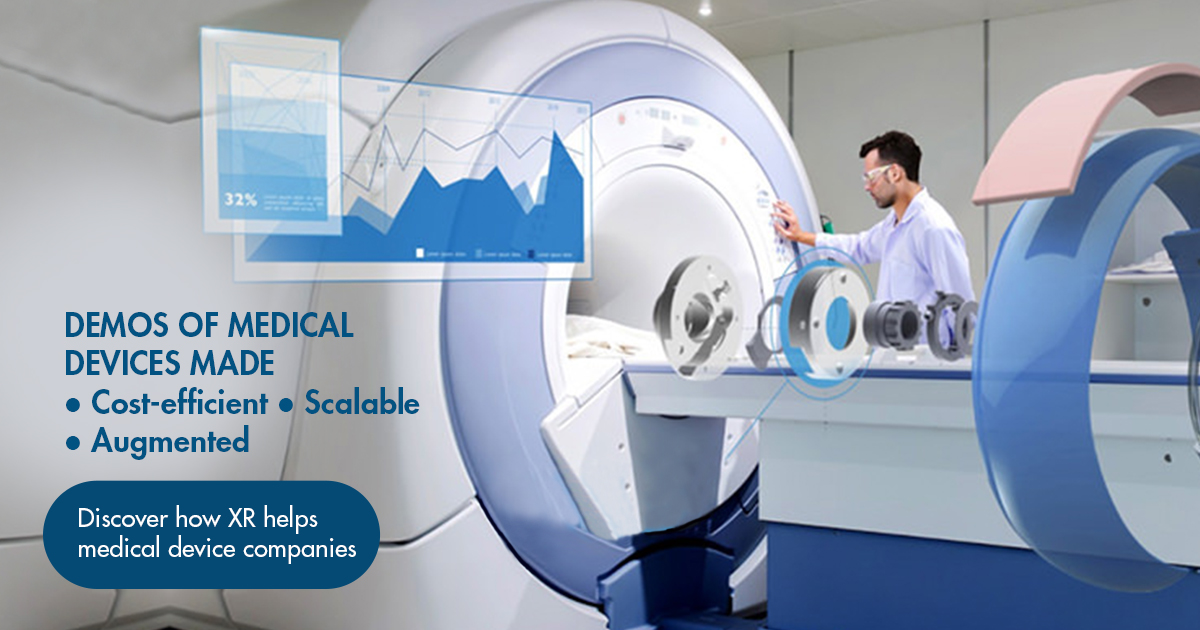

The concept of AR/VR is not new to the pharmaceutical industry.AR/VR has made in-roads from product demos to drug discovery. AR/VR has unlimited potential and can address the need for greater control over quality and safety standards. Auditing involves analyzing business processes and recommending solutions. Large manufacturers do audit their suppliers and contractors to ensure they follow best practices for manufacturing. While pharma auditing remain as a niche segment, it plays a key role in quality control and hence the product lifecycle and brand reputation. XR is enhancing efficiency and safety with process optimization. The risks involved in pharma manufacturing are high, where the consequence of mistake can damage the entire product development cycle and brand reputation.

Using XR lowers human error and allows maintaining a high level of regularity in products — for example, developing medicine with various chemicals involved, along with using visual and audio prompts, ensures product excellence while cutting down on dosage error. This also addresses the need for experienced professionals as this tool can train staff and avoid process divergence through virtually guided instruction. Not just this, XR in this process can help quality auditors to visualize this from remote location real-time thereby digitally approving the quality standards.

While for pharma auditors XR enables the remote quality assessment; for pharma suppliers, AR/VR solution improves product/process quality, audit readiness quality, safety in the lab environments. XR enables the pharma companies to address the supplier regulation compliance and auditing to ensure the entire process is optimized. XR in quality auditing can encourage synergistic relations between the company and its suppliers as management can audit the quality and monitor suppliers’ real-time using this smart technology to ensure GMP regulation.

Life cycle of Quality Audit using XR

While most of the internal audits are reviewed by management, XR can help in 3D projection and highlight potential areas of risk for further deep dive. Also, it offers real-time insights on the process and product quality standards for use in the management reviews and investor presentations to gain brand confidence/loyalty. XR can be used to detect potential defects on high-speed manufacturing lines. Pharma auditors can do a virtual tour on the manufacturing floor using the smart glass used by the floor assistant. XR technology coupled with AI can be used for a quality check along with pre-saved regulatory information on a global basis that can help the pharma companies to adhere to the global regulatory standards and even highlight the impact on the company’s product portfolio. For example, it can spot insufficient depth in investigations into the root causes of complaints and non-conformances of regulations.

Enterprise-level engagement and collaboration are very important to work together with greater reliability. Using smart glasses employees now host sessions among different divisions within the company to instantly share critical information swiftly, and securely. Thus companies can keep enterprise data precise and structured, with easy access to data globally.

Scientists spend more than 30% of their lab time in transcribing process Documentation during product development and process handling is a major hassle for scientists and line workers. This also applies to the pharma auditors during inspection. Smart glasses with AR can collect audio notes, video clips, pictures, sample volumes, numerical data and much other information along transcribing them digitally with AI assistance reducing load on scientists. This allows all the vital information to be recorded virtually enhancing the productivity and efficiency.

Does VR play a role here? Definitely, the information captured can be made into a virtual projection to understand the effectiveness of the solution developed.

XR is the next solution for pharma companies to further enhance safety and efficiency while providing real-time visibility into vital information tracking and audit readiness. Whereas for pharma auditors AR/VR provides remote access to inspect process cycle and product development.

Augray’s Value Addition

In the wake of the COVID-19 crisis, AR technology has gained traction more than twice or thrice than the expected. Augray believes digital quality auditing can influence the collective knowledge of an enterprise and expand it radically. It will allow the faster development of new medicines as well as improve the speed to market. Augray identified XR can augment human capability by automating the entire quality audit process.

“While the industry follows traditional and obsolete methods that are complex and slow, Augray’s XR platform simplifies and accelerates the pharma audit process by allowing quality to be tracked in real time from any smart device”, says Senior Director of Augray.

While the pharma industry is slowly transforming and adopting digital services, AR is expected to move from sales to mainstream activities. Augray recognized this opportunity and aims to transform this space with its XR product. Augray has committed to the creation of a high-quality customer-centric product that offers benefits such as transparency, efficiency, and precision. The adoption of AR can help companies streamline their pharma auditing process and eliminate manual SOP management.

With remote working to mainstream post-COIVD-19 world, pharma companies are searching out ways to reduce human intervention and assure remote assistance in operations. Pharma companies are specifically using AR for AI-assisted guided instruction software that can monitor and make the product cycle audit-ready. Pharma auditors use AI-assisted smart lens to analyze the product and process development cycle along with cross-checking them to GMP regulations. Augray’s scalable solution can fill this void in the pharma space and make pharma auditing an augmented remote operation.